Aluminium is one of the most popular production materials on the planet. It is strong yet lightweight, making it ideal for everything from canning drinks to building consumer electronics. However, producing new aluminium is highly energy-intensive, and manufacturing methods leave a large carbon footprint.

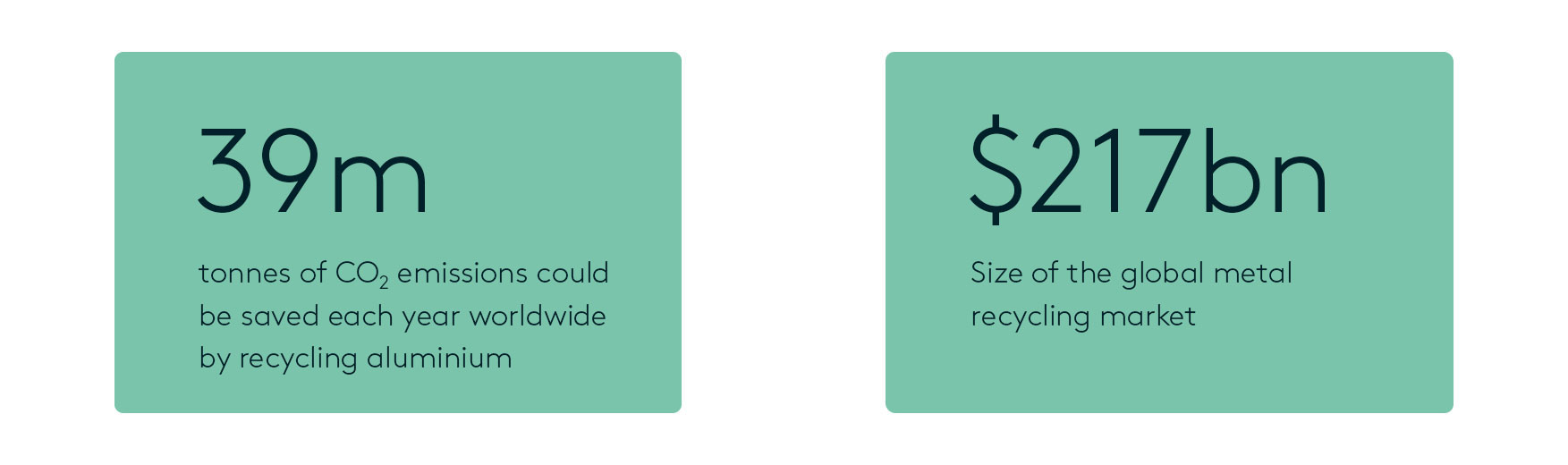

Aluminium is an infinitely recyclable material. Recycling scrap aluminium takes up to 95% less energy than producing new aluminium. This means a much smaller carbon footprint for manufacturers and consumers alike, as well as lower costs. The consumer demand for goods containing aluminium is growing each year. As governments impose more environmental regulations on mining, and as consumer demand shifts to more sustainable options, the race is on to find quick and efficient ways to recycle the aluminium that is already in circulation, rather than manufacturing it from new.

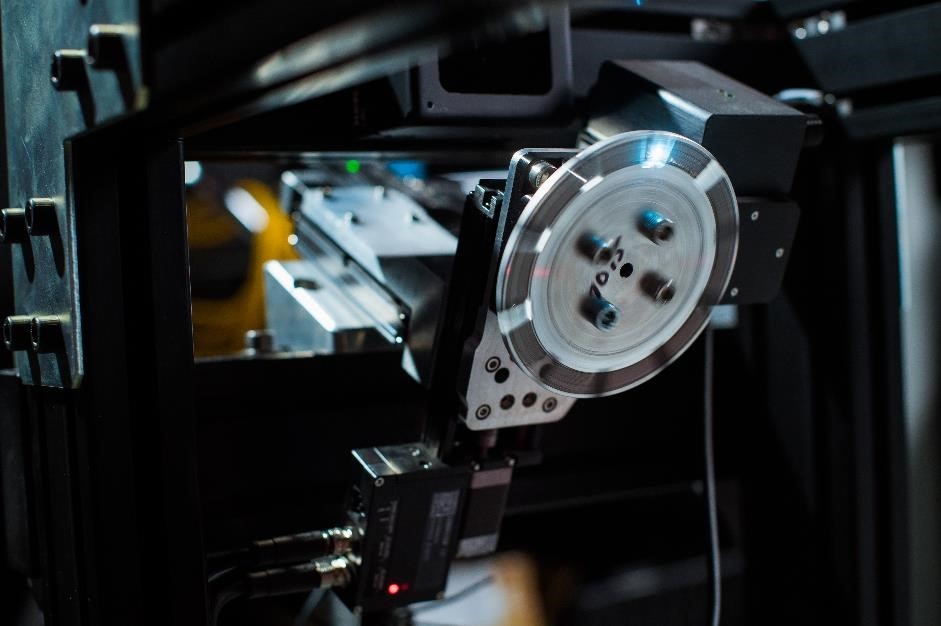

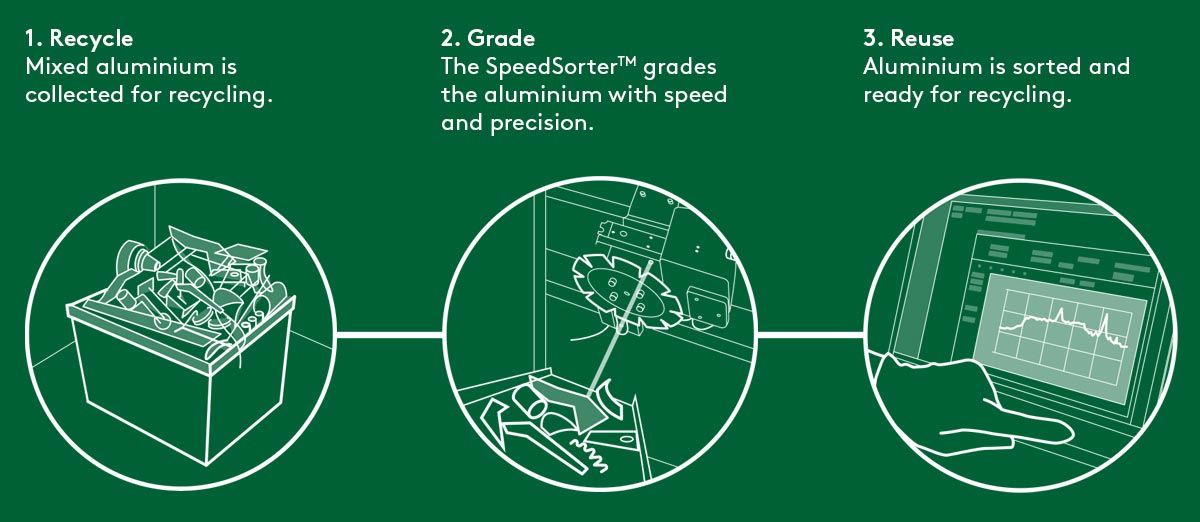

Recycling aluminium is a process that demands speed and precision. Ocean Insight, a company that specialises in optical sensing technology to analyse light, has designed a new device that offers both. Its SpeedSorter™ quickly and accurately sorts scrap aluminium into its distinct types before it can be taken away to be melted down and recycled. The SpeedSorter™ uses Laser-Induced Breakdown Spectroscopy, which allows it to quickly determine the chemical composition of each aluminium scrap object and communicate the result to a sorting system. Separation of aluminium from different metals is easily performed in milliseconds. This means the aluminium is separated and sorted at speed, and is then ready to go back into circulation.

Ocean Insight’s technology is one of many in the Halma Group that is delivering an innovative solution to protect our planet’s resources. As resources become scarcer the demand for such technologies represents a long-term trend that is set to keep growing for decades.